Stage 1: Vision, Consultation, and Planning

Stage 1: Vision, Consultation, and Planning

Overview:

The first thing to have when designing a commercial kitchen is of course the vision. You need to have an idea about the type of kitchen, the location, the design, the size, and the general mode of operation.

As a kitchen hospitality design specialist, we go over this information in detail. The initial plan will be explored, reinforced, and made feasible, allowing for budget constraints, local council regulations, finance options, and a more specifically attuned equipment list.

Sub-Steps:

- Formulate a clear and thought-out plan.

- Consultation with professionals.

- Budget / finance plan & equipment ideas.

Stage 2: Site-Visit, Preliminary Design, and Plan Adaptation

Stage 2: Site-Visit, Preliminary Design, and Plan Adaptation

Overview:

After the initial step you should have a well-rounded idea that fits both your initial vision and the commercial kitchen consultant’s advice. From here, the next step is a visit to the site to get measurements and an experience of the area. This new information is then brought back to the original plan where adjustments are made.

Sub-Steps:

- Site measured and information recorded.

- Layout sketched and updated with new information.

- Plan adapted and updated to suit new details.

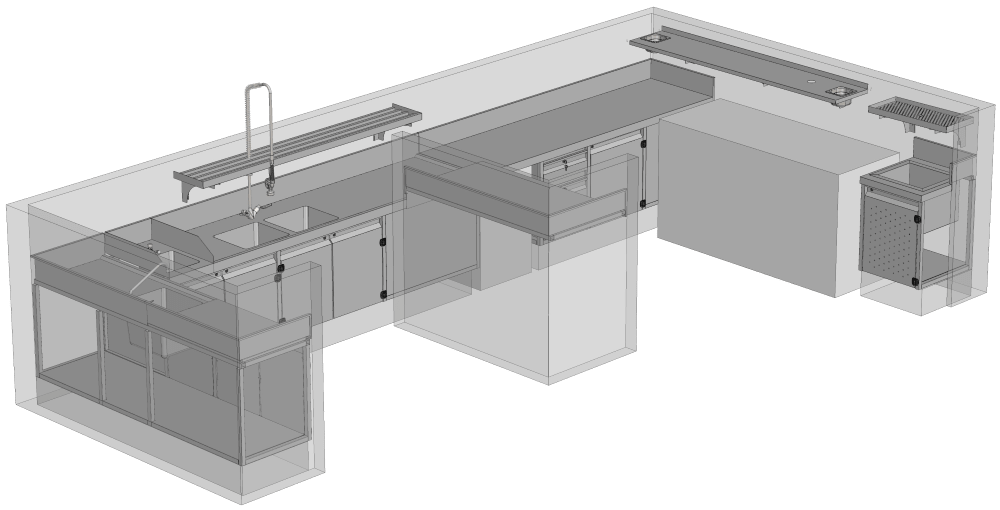

Stage 3: CAD Drawing and Technical Design

Stage 3: CAD Drawing and Technical Design

Overview:

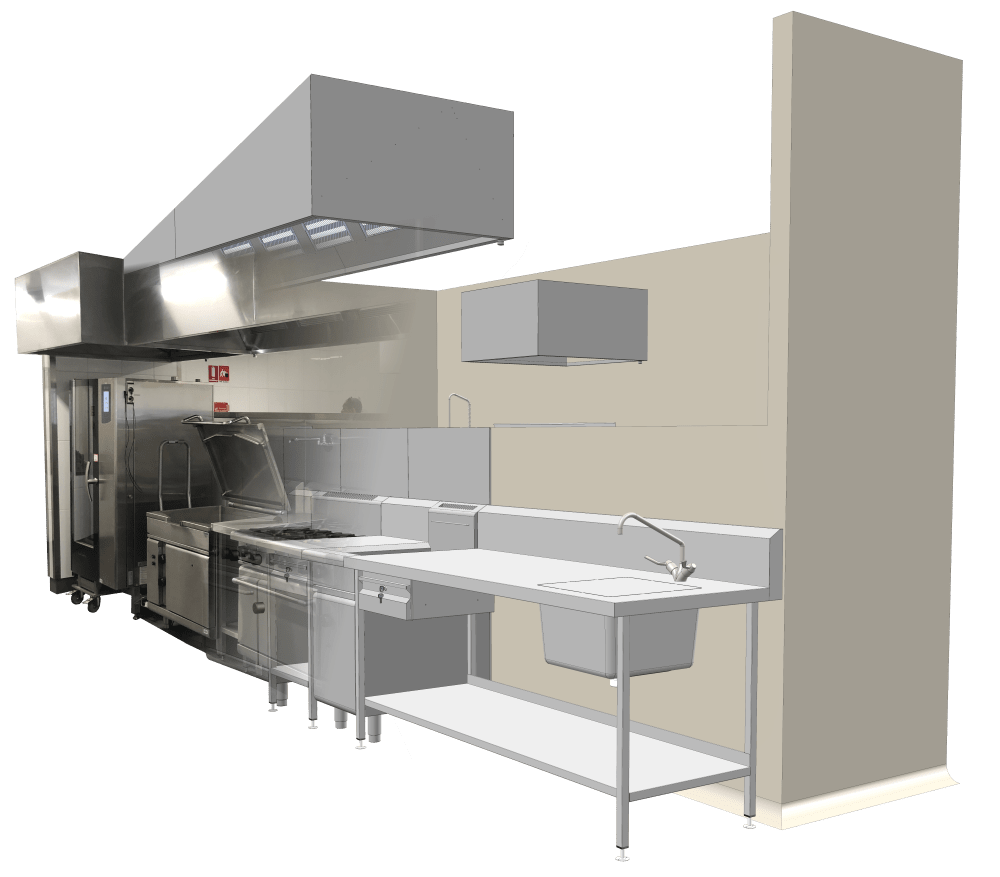

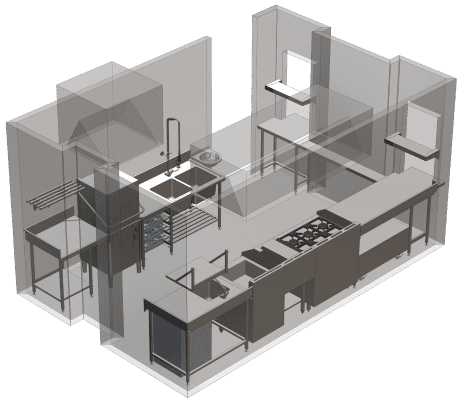

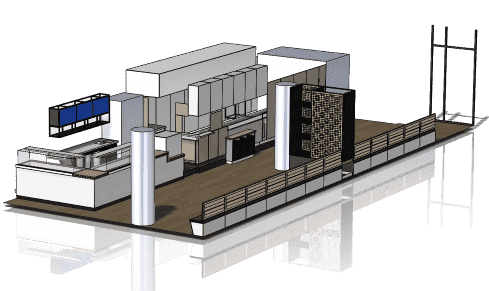

Now that the vision is fully thought-out, the site has been measured, and the details are collected the technical designing can begin. Our in-house design team create a 3D representation of the kitchen-to-be that offers a glimpse of the finished product from any angle. This allows for extremely precise attunement of the design and the equipment that may include custom fabrication options.

Sub-Steps:

- Kitchen representation created as 3D model.

- Design specification documents created.

- Customised items designed and added.

Stage 4: Custom Design and Fabrication

Stage 4: Custom Design and Fabrication

Overview:

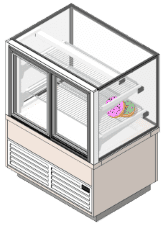

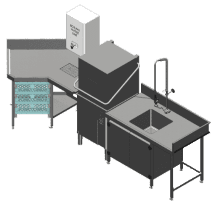

Commercial kitchens come in a variety of shapes and sizes, as you would know by this stage. As such, the large stainless steel kitchen equipment and surfaces will likely need to be customised in order to optimise the space and flow of the kitchen. Our design team create (and modify) custom stainless steel items including benches, canopies, and wall sheeting, refrigerators and other large items. This is carried out by our in-house fabrication team.

Sub-Steps:

- Custom items designed and added to plan.

- Customised equipment drawn-up and added.

- Items are fabricated and prepared for delivery.

Stage 5: Delivery and Installation

Stage 5: Delivery and Installation

Overview:

Once the custom items have been made, and the equipment that needed customisation has been modified, the next stage is to get everything delivered and installed. This process includes getting the dates and times set, having all the right people ready to work, and getting everything moved, fitted, attached, plugged in, plumbed up, and finally taking off the scratch-resistant plastic.

Sub-Steps:

- Installation plan made.

- Items packed up and delivered.

- Kitchen equipment and items installed.

Stage 6: Completion and Service

Stage 6: Completion and Service

Overview:

Once everything is installed and the kitchen is ready to use the next step is to deliver all the small kitchen items that you need (pots, pans, spatulas, and so on). After that, the kitchen is completely fitted out. You will have a collection of user-manuals, documentation and other important paperwork that should be stored away securely. If you need service or support, call us.

Sub-Steps:

- Kitchen stocked with small items.

- Paperwork is securely and safely stored.

- Our phone number is ready in case of service or support.

Value Management

By optimising the value-to-cost ratio of kitchen equipment & design option, we can enhance the effectiveness of your fitout while reducing the total cost of the quote. We can also adjust the fitout design so that, by perhaps initially investing a bit more, the resulting kitchen will be much more durable, efficient, and future-proof. This comes down to your vision, budget, future plans, and the particular type of fitout you want.

Project Management

Our team is familiar with all of the hurdles of creating a commercial kitchen: tweaking the initial idea to fit the location; constraining the plans to ensure well utilised space; balancing design and function; custom designing units to fit the plan; navigating government regulations. As an experienced restaurant consultant, we plan, design, project manage, organise installation / delivery, organise financing, maintain a dialogue with the client, and deal with virtually every part of the commercial kitchen creation process.

Specialty Kitchen

Brandon Industries was founded in Moorabbin in 1975. More than 40 years of experience within the industry has given us the knowledge and know-how that allows for optimal design and fabrication of specific commercial kitchen fitouts. As shown by our completed fitouts, we have a wide history of designing kitchens for varying clients. The areas that these clients come from range from cafés and restaurants to aged-care facilities and not-for-profits.

Recent Commercial Kitchen Projects

Completed Fitouts

Awarded Tenders

Want to know more?

Please give us a call on (03) 9555-3333 or via our online consultation form below.

Consultation Review Us

Kitchen Types and Markets

All sorts of kitchen design for all sorts of situation.

Stainless Steel Design

Design, fabrication and delivery of custom stainless steel.

SEE OUR STAINLESS STEEL OPTIONS >

Our Services

Project Management, Specialty Kitchen Projects Custom Stainless Steel, Preparation and Installation Design and Fitout, Finance and Rent-to-Buy

Contact Us

Our Store

- Address: 55-57 Progress Street, Dandenong South, VIC, 3175

- Phone number: +613 9555 3333

- Email: enquiry@brandon.com.au

- Open hours: Monday to Friday: 8:30 am to 5:00 pm